当前位置:首页>>广州有道有限元>>ANSYS有限元分析

ABAQUS计算指导5:应用壳单元计算轴对称问题

;

;

有内压的容器或弹性元件,其工作方式分为两类。第一类内压是通过调节而保持恒定的。对于恒压情况,内压p不随变形改变。第二类是密闭容器。如空气弹簧、篮球等情况,施加外载荷后内压是随变形改变的,采用常内压p无法模拟这一变化。另外,在计算时所称的“内压”实际上是内部压强与环境压强的压差,这时造成变形的有效载荷。

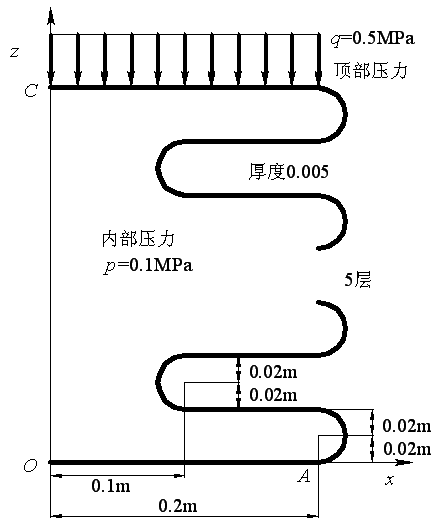

用轴对称壳单元模拟铍青铜充压弹簧,材质E=35GPa,μ=0.33。弹簧顶部承受外载荷q=0.5MPa,内压p=0.1MPa(加载前初始内压与环境的压差),不计重力。计算最大Mises应力,最大z轴位移。

如下是该题按常内压求解的算例,ExpAbq05,命令流为ExpAbq051.inp。本题作为密闭容器的变内压解法见命令流ExpAbq052.inp,因为变形很大,两种情况的求解结果大不一样。

文件与路径

顶部下拉菜单File, Save As ExpAbq05。

一 部件

创建部件,命名为Prat-1。

轴对称,可变形模型,线,图形大约范围1(m)。

选用线和圆弧绘出图示的截面壳的中线。造1层,拷贝5层,修正后完成Part-1。

二 性质

1 创建材料:

将材料命名为Material-1,输入E=35GPa,ν=0.33,关闭。

2 创建截面:

名为Section-1,壳,各向同性,材料名选Material-1,厚度0.005m,关闭。

3 将截面的性质附加到部件上:

选中Prat-1,将Section-1信息注入Part-1。

三 组装

创建计算实体,以Prat-1为原形,用Independent方式生成实体。

四 分析步

创建分析步,命名为Step-1,静态Static,通用General。

注释:无,时间:不变,非线性开关:关。

五 载荷

1 施加位移边界条件:

命名为BC-1,在分析步Step-1中,性质:力学,针对位移和转角。

选中轴上两线端点O、C,约束自由度x。

命名为BC-2,在分析步Step-1中,性质:力学,针对位移和转角。

选中底线OA,约束自由度y。

2 创建载荷:

命名为Load-1,在分析步Step-1中,性质:力学,选择压强,选中顶线,选择外侧,值=0.5e6。

命名为Load-2,在分析步Step-1中,性质:力学,选择压强,选中各线,选择内侧,值=0.1e6。

六 网格

对部件Prat-1进行。

1 撒种子:

针对部件,全局种子大约间距0.005m。

2 划网格:

针对部件,OK。

七 建立项目

命名为ExpAbq05,选择完整分析,其余不变,OK。

八 观察结果

打开结果文件ExpAbq05.odb,看位移彩图。

在上述过程中不时地将本题的CAE模型保存为ExpAbq05.cae。

命令流

*Heading

** Job name: ExpAbq051 Model name: Model-1

*Preprint, echo=NO, model=NO, history=NO, contact=NO

**

** PARTS

*Part, name=Part-1

*End Part

**

** ASSEMBLY

*Assembly, name=Assembly

*Instance, name=Part-1-1, part=Part-1

*Node

1, 0.0, 0.0

41, 0.2, 0.0

61, 0.2, 0.04

81, 0.1, 0.04

101, 0.1, 0.08

121, 0.2, 0.08

141, 0.2, 0.12

161, 0.1, 0.12

181, 0.1, 0.16

201, 0.2, 0.16

221, 0.2, 0.2

241, 0.1, 0.2

261, 0.1, 0.24

281, 0.2, 0.24

301, 0.2, 0.28

321, 0.1, 0.28

341, 0.1, 0.32

361, 0.2, 0.32

381, 0.2, 0.36

421, 0.0, 0.36

*Ngen, ,Nset=Part1

1, 41, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

41, 61, 1, ,0.20,0.02,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

61, 81, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

81,101, 1, ,0.10,0.06,0.00,0.00,0.00,-1.00

*Ngen, ,Nset=Part1

101,121, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

121,141, 1, ,0.20,0.10,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

141,161, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

161,181, 1, ,0.10,0.14,0.00,0.00,0.00,-1.00

*Ngen, ,Nset=Part1

181,201, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

201,221, 1, ,0.20,0.18,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

221,241, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

241,261, 1, ,0.10,0.22,0.00,0.00,0.00,-1.00

*Ngen, ,Nset=Part1

261,281, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

281,301, 1, ,0.20,0.26,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

301,321, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

321,341, 1, ,0.10,0.30,0.00,0.00,0.00,-1.00

*Ngen, ,Nset=Part1

341,361, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

361,381, 1, ,0.20,0.34,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

381,421, 1, , , , , , ,

*Element, type=SAX1

1, 1, 2

*ELGEN, ELSET=Part1

1, 420, 1, 1

** Section: Section-1

*Shell Section, elset=Part1, material=Material-1

0.005, 5

*End Instance

**

*Nset, nset=DUX, internal, instance=Part-1-1

1, 421

*Nset, nset=DUY, internal, instance=Part-1-1

1, 41,1

*Elset, elset=SurfQE, internal, instance=Part-1-1, generate

380,420,1

*Surface, type=ELEMENT, name=SurfQS, internal

SurfQE, SNEG

*Elset, elset=SurfPE, internal, instance=Part-1-1, generate

1,420,1

*Surface, type=ELEMENT, name=SurfPS, internal

SurfPE, SPOS

*End Assembly

**

** MATERIALS

*Material, name=Material-1

*Elastic

3.5e+10, 0.33

** ----------------------------------------------------------------

** STEP: Step-1

*Step, name=Step-1

*Static

1., 1., 1e-05, 1.

**

** BOUNDARY CONDITIONS

** Name: BC-1 Type: Displacement/Rotation

*Boundary

DUX, 1, 1

** Name: BC-2 Type: Displacement/Rotation

*Boundary

DUY, 2, 2

** LOADS

** Name: Load-1 Type: Pressure

*Dsload

SurfQS, P, 500000.

** Name: Load-2 Type: Pressure

*Dsload

SurfPS, P, 100000.

**

** OUTPUT REQUESTS

*Restart, write, frequency=0

** FIELD OUTPUT: F-Output-1

*Output, field, variable=PRESELECT

** HISTORY OUTPUT: H-Output-1

*Output, history, variable=PRESELECT

*End Step

*Heading

** Job name: ExpAbq052 Model name: Model-1

*Preprint, echo=NO, model=NO, history=NO, contact=NO

**

*PHYSICAL CONSTANTS, ABSOLUTE ZERO=-273.15

**

** PARTS

*Part, name=Part-1

*End Part

**

** ASSEMBLY

*Assembly, name=Assembly

*Instance, name=Part-1-1, part=Part-1

*Node

1, 0.0, 0.0

41, 0.2, 0.0

61, 0.2, 0.04

81, 0.1, 0.04

101, 0.1, 0.08

121, 0.2, 0.08

141, 0.2, 0.12

161, 0.1, 0.12

181, 0.1, 0.16

201, 0.2, 0.16

221, 0.2, 0.2

241, 0.1, 0.2

261, 0.1, 0.24

281, 0.2, 0.24

301, 0.2, 0.28

321, 0.1, 0.28

341, 0.1, 0.32

361, 0.2, 0.32

381, 0.2, 0.36

421, 0.0, 0.36

*Ngen, ,Nset=Part1

1, 41, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

41, 61, 1, ,0.20,0.02,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

61, 81, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

81,101, 1, ,0.10,0.06,0.00,0.00,0.00,-1.00

*Ngen, ,Nset=Part1

101,121, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

121,141, 1, ,0.20,0.10,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

141,161, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

161,181, 1, ,0.10,0.14,0.00,0.00,0.00,-1.00

*Ngen, ,Nset=Part1

181,201, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

201,221, 1, ,0.20,0.18,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

221,241, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

241,261, 1, ,0.10,0.22,0.00,0.00,0.00,-1.00

*Ngen, ,Nset=Part1

261,281, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

281,301, 1, ,0.20,0.26,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

301,321, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

321,341, 1, ,0.10,0.30,0.00,0.00,0.00,-1.00

*Ngen, ,Nset=Part1

341,361, 1, , , , , , ,

*Ngen,Line=C ,Nset=Part1

361,381, 1, ,0.20,0.34,0.00,0.00,0.00,1.00

*Ngen, ,Nset=Part1

381,421, 1, , , , , , ,

*Element, type=SAX1

1, 1, 2

*ELGEN, ELSET=Part1

1, 420, 1, 1

*Node

1000, 0.00,0.18,0.00

*Nset, nset=CAVITY, internal

1000,

** Section: Section-1

*Shell Section, elset=Part1, material=Material-1

0.005, 5

** FLUID ELEMENTS

*ELEMENT, TYPE = FAX2, ELSET = FLUID

501,1,2

*ELGEN, ELSET = FLUID

501,420,1,1

*FLUID PROPERTY, REF NODE=CAVITY, TYPE=HYDRAULIC,

ELSET=FLUID, AMBIENT=100000.00

*FLUID DENSITY, PRESSURE=100000.00, TEMPERATURE=27.0

1.0432,

*End Instance

**

*Nset, nset=CAVITY, internal, instance=Part-1-1

1000,

*Nset, nset=DUX, internal, instance=Part-1-1

1, 421

*Nset, nset=DUY, internal, instance=Part-1-1, generate

1, 41,1

*Elset, elset=SurfQE, internal, instance=Part-1-1, generate

380,420,1

*Surface, type=ELEMENT, name=SurfQS, internal

SurfQE, SNEG

*End Assembly

**

** MATERIALS

*Material, name=Material-1

*Elastic

3.5e+10, 0.33

** ----------------------------------------------------------------

** STEP: Step-1

*Step, name=Step-1, nlgeom=YES

*Static

1., 1., 1e-05, 1.

*MONITOR, NODE=CAVITY, DOF=8

** BOUNDARY CONDITIONS

** Name: BC-1 Type: Displacement/Rotation

*Boundary

DUX, 1, 1

DUY, 2, 2

CAVITY,8,8,100000.00

**

** OUTPUT REQUESTS

*Restart, write, frequency=0

** FIELD OUTPUT: F-Output-1

*Output, field, variable=PRESELECT

** HISTORY OUTPUT: H-Output-1

*NODE OUTPUT, NSET=CAVITY

CVOL,PCAV

*Output, history, variable=PRESELECT

*End Step

** ----------------------------------------------------------------

** STEP: Step-2

*Step, name=Step-2, nlgeom=YES

*Static

1., 1., 1e-05, 1.

*MONITOR, NODE=CAVITY, DOF=8

** BOUNDARY CONDITIONS

** Name: BC-1 Type: Displacement/Rotation

*Boundary, OP=NEW

DUX, 1, 1

DUY, 2, 2

** LOADS

** Name: Load-1 Type: Pressure

*Dsload

SurfQS, P, 500000.00

** OUTPUT REQUESTS

*Restart, write, frequency=0

** FIELD OUTPUT: F-Output-1

*Output, field, variable=PRESELECT

** HISTORY OUTPUT: H-Output-1

*NODE OUTPUT, NSET=CAVITY

CVOL,PCAV

*Output, history, variable=PRESELECT

*End Step